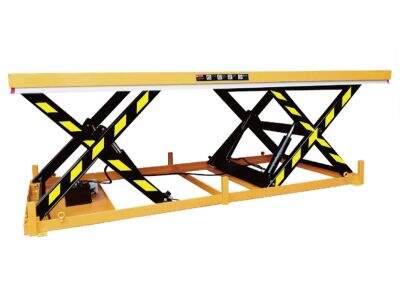

Maintenace of your NOBLELIFT Lift Table is crucial to keep it in good working condition. Regular maintenance is not only a good idea though, it's absolutely necessary as this is what will help your lift table last longer and stay safe for everyone to use. By taking the time to properly care for your equipment, you can prevent quite a few issues that may occur down the road. To ensure your lift table is in peak condition at all times, we have compiled a list of 5 easy basic ways you can care for and maintain it.

5 Easy Methods of Maintenance for Lift Tables

Keep It Clean

Simple and easily one of the most effective, is keeping your lift table clean. Always wipe clean the table surface and its parts This helps preventing dust and dirt from accumulating, which otherwise could cause all kinds of problems longer term. You can even use compressed air to spray away small amounts of dirt that may become lodged in those nooks and crannies. This is a small thing that you can do but keeping everything clean means a lot.

Check the Fluids

Fluid Check on Lift Table For optimal performance of your lift table, you need to check the fluids regularly. This involves checking hydraulic oil, gear oil and brake fluid levels. These fluids are important for the smooth performance of your lift table. Always refer to your owner's manual for when and how often to change these fluids and always use the correct types specified in the manual. By you simply maintaining your lift table, it will assist in the longevity of life.

Inspect the Components

This is important to prevent problems in the future and avoid jeopardizing your safety. Examine the lift table for damage: Cracks, leaks or rust anywhere on different parts of the Electric Forklift table. And if you see any concerns, it is in your best interest to catch them early. Addressing minor problems promptly will cut down on costly repairs in the future and keep you up and running.

Lubricate Moving Parts

Lubrication of the parts that move is very important when you are maintaining your lift table in working condition for a long time. This relates to everything from the scissor legs to wheels and bearings that must be free to move for proper operation. Use a good quality lubricant and be careful to follow the procedures indicated in the user manual. For the same reason, lubrication is also important for these parts to enable them to work perfectly and prevent from wear and tear.

Keep a Maintenance Schedule

A scheduled maintenance is a great way to remind you when all the important things that needs to be done for your Lift Table. The more tasks you should do; the more detailed list is required, noting what to do and how often to do it. This can be a good way to stay organized and keep up with your maintenance work. This allows you to check things off your list in time and hopefully help keep your lift table in good running order.

Why You Should Maintain Your Lift Table

The care of your lift table is not only in keeping it clean but also that it works well and safely. You should take care of your equipment and maintain them if you want to get the superior services from these. It not only helps in avoiding break downs but also increases the operating life of lift table and allowing you to use it more. Furthermore, the person using the Full-Electric Pallet Truck table as well as anyone working around it will be at much less risk of injury if the lift table maintenance has been properly taken care of. NOBLELIFT is all about safety and hence we highly recommend the way in which maintenance should be carried out, so more it will comply with safety performance.

Maintenance Tasks for Lift Tables Most of the time, lift tables actually require fairly little maintenance.

Some of the most typical activities that you should perform to keep your lift table in excellent condition. The work that must be done is to see the hydraulic system for any leakage or damage, operate the lift system in proper order & check whether the leveling system exists or not. It is also important that you check the wheels and bearings since they are vital to the lift table. Also, ensure all the movements are shiny and continuously working and perform oil checks as well as changes. Ensuring that all fluids are spelled at the right levels and there is no other hidden type so grass will become smooth in terms of manner. Keeping up with these items will help your lift table last longer and avoid expensive downtime.

The Time and Dollar Costs Maintenance Helps You Avoid

By loving and taking care of your lift table, you could save a ton of money (and time) in the long run. This will help you avoid unexpected repairs, therefore reducing the downtime and cost associated with machine breakdowns. Repairs costs are almost always going to be significantly higher than maintenance costs, even the more specialized kind of upkeep you can get through an auto detailing service. In addition to this a properly serviced lift table will have better working time that can lead to faster job completion and greater efficiency in work. A broken lift table could cost you in downtime, delay your workload and hold up shipments. Knowing why your lift table stopped working can prevent you from delayed operations which eventually keeps your business up and in running with less downtime.

So use these points and regular maintain your NOBLELIFT lift table for safe operations at work flow. With these simple maintenance tips and keeping on top of your scheduled tasks, you will not only be able to make sure that your lift table provides a longer service life, but this is how you prevent costly problems and ensure everything operates smoothly.

Table of Contents

- 5 Easy Methods of Maintenance for Lift Tables

- Keep It Clean

- Check the Fluids

- Inspect the Components

- Lubricate Moving Parts

- Keep a Maintenance Schedule

- Why You Should Maintain Your Lift Table

- Maintenance Tasks for Lift Tables Most of the time, lift tables actually require fairly little maintenance.

- The Time and Dollar Costs Maintenance Helps You Avoid

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

ES

ES